Kitchen Island, Barn Power – March 2024 Update

Welcome to my shop! This is a quick update to let you know what I’ve been up to. This big chunky thing is the leg

So this time we’re going to cover the registration process in a decent detail, wrap things up, and just sort of summarize things, and hopefully fill in any little gaps and holes in the story. So we’re gonna cover how I got this first. Now of course, this process is going to vary depending on where you’re at, even here within the US it’s going to vary depending on the state you’re in, maybe it’s similar to this, maybe it’s something totally different, but I’m just going to focus on my experience getting a homemade trailer titled in the state of Minnesota.

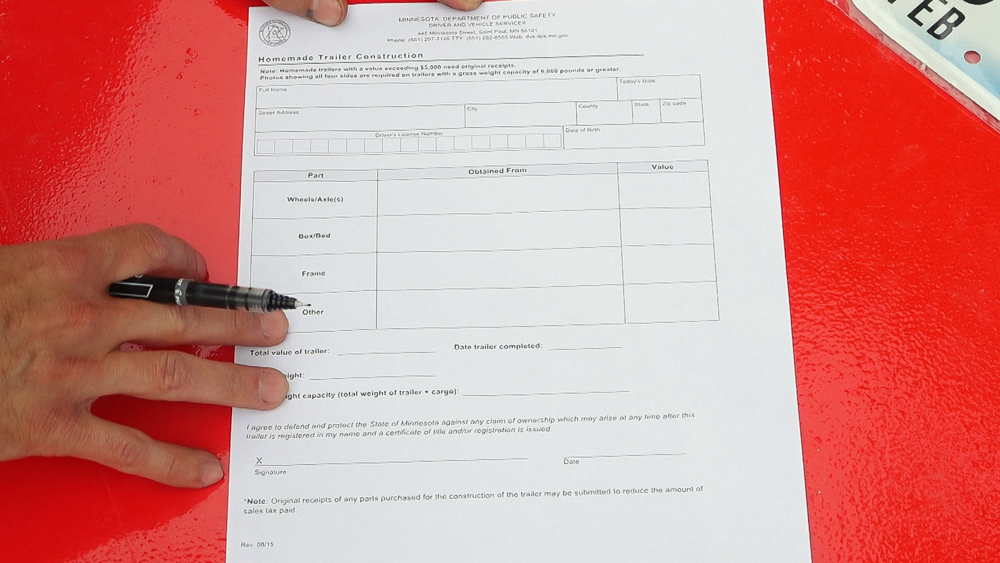

And it all starts with this guy here, the Department of Public Safety’s homemade trailer registration form. This form covers everything you need to apply for a title for your trailer, and this is going to dictate the flow of this post. Looking through the form, we can see the things that we’re going to need in order to apply for our title.

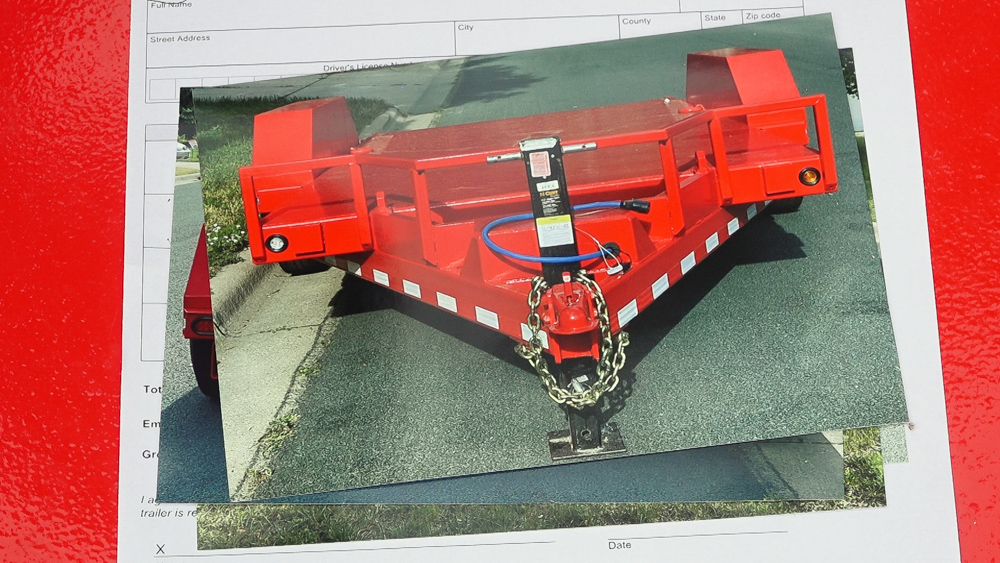

So easiest thing first, photos of all four sides of the trailer. That’s pretty easy. Took some pictures on the phone, got them printed out, and there we go. I haven’t gotten prints in a very long time, so step one done.

So now the next easiest thing to knock out is going to be weight, and on a trailer, figuring out the weight of this thing is actually fairly easy and this is going to tie into the receipts part. So a lot of the weight of this trailer is pretty well known. You have a good idea of exactly how much steel you used, so you can easily know what the actual total amount of steel is going into this thing and then you have an idea of how much everything else beneath the steel weights, so the stuff that connects the steel thing to the ground.

So because it’s kind of fun, I broke it out a little bit, and we’re gonna go back in time and just walk through this thing as it was getting heavier and heavier.

So the first thing is the frame. So when I had the entire frame welded up together, and I was spinning it around on the sawmill, that total weight at that point was 711 pounds. The next thing I did is I brought the two tongue pieces on, those each were weighing in at 117.5lbs, so with the two tongue members on there, that’s 235 pounds added to the 711, that’s 946lbs. The next big thing to go on was the decking, that’s two sheets of 10 gauge steel, each sheet weighs 225lbs. So that adds 450lbs to the total weight of the trailer. Now we’re at 1,396. Next is going to be the chain tray and the safety rails, that added 140lbs, so that’s 1536. The rear light bar, which was a staggering 35 pounds. The next thing was the fenders. They’re made out of one sheet of that 10 gauge steel, plus some tube. Again, the 10 gauge steel sheet is 225 pounds plus a bit of tube stock, so each fender weighs about 120lbs. We’ll add that onto our total, we’re at 1,811lbs. Another big thing that I put on was the front jack, that was 64lbs. So that’s 1,876lbs.

Now for some of the surprisingly heavier things, everything that connects this trailer to the ground. So the axles were each coming in at 45lbs, the backing plates for the brake assemblies, those were each 12lbs, the brake drums were 35lbs, and then the tires themselves are each 82 pounds. They also have the springs in there with the hangers and all that hardware, so that whole assembly, those two axle complete assemblies with suspension adds another 600 pounds to the total weight of the trailer bringing my little weigh-in total here to 2,476lbs.

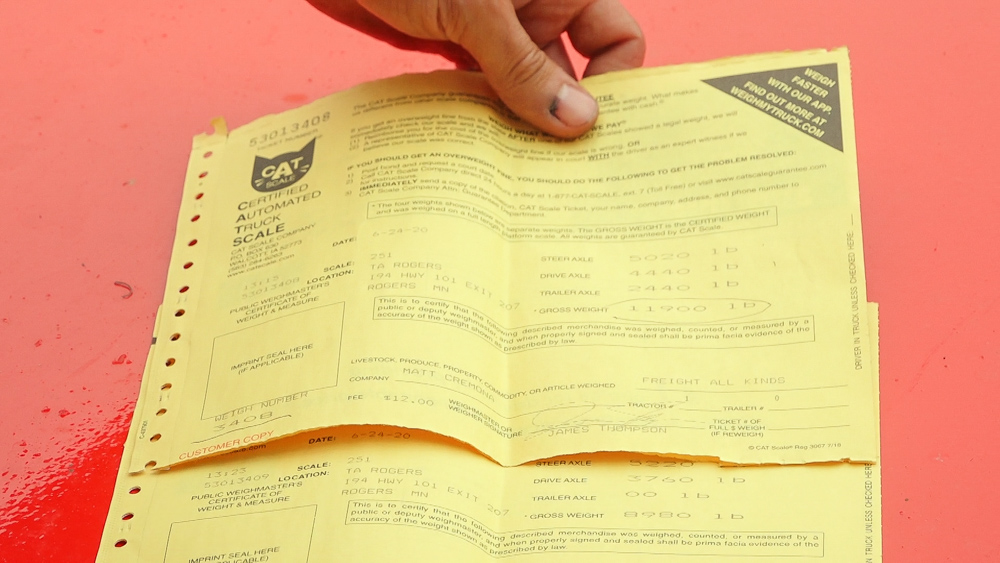

So that total told takes care of the bigger stuff, and then you start thinking about all the smaller things that are on here, like this adjustable coupler mount, the actual coupler itself, stake pockets, the giant D-rings, my light boxes, everything else that’s not really counted on that, the lights, the wiring, everything like that, so you just throw a number at that, and that would be close enough for most instances. So my guess is this thing would probably weigh around 2800lbs or so, but I know an educated guess probably isn’t good enough for a lot of you, so let’s head to the scale and get an actual weight on this thing.

The bottom ticket here is just the weight of my truck alone: 8980lbs. The top one is the combined truck and trailer, so just under 12,000 pounds. The difference between them is 2,920 pounds. So that’s the weight of the trailer.

So we have our photos, now we have our weight. Let’s just talk about the gross weight capacity of the trailer. So if you’re operating commercially, there are sort of two numbers you have to consider and think about. The first number is 10,000 pounds. That is going to be a weight rating of a trailer being towed. And at that point, you need to have a DOT number, and you need to have a medical card. A DOT number is very easy to obtain, it’s basically just telling the government that you are operating, and the medical card is a very, very basic and simple physical exam. I got mine in like a half-hour, and you’re in and out, and it costs like $70. So it’s not a huge hurdle to get into that 10,000 pound mark. That’s why you’ll see a lot of trailers with tandem 5,000 pound axles rated for 9,990 so that the drivers are underneath that 10,000 pound limit and don’t need those two things.

The other number you need to keep in mind is 26,000 pounds. That is going to be the maximum combined gross weight rating of the tow vehicle and the trailer that you can move with a regular license before you need a commercial license. So normal licenses are class D, so on the back of my license here in Minnesota, it’s got the restriction right there. I can drive up to a combination of 26,000 pounds, but you can see, we had exemptions for recreational vehicles and farm vehicles. So if you happen to live on a farm and you’re driving stuff back and forth from that farm as part of your agricultural business, you’re exempt, or if you get whatever you’re driving classified as an RV, you’re also exempt from that. So that means you need to start thinking about the vehicle you’re gonna use to tow your trailer, and keeping that combination at 26,000 pounds or less. So in my case my truck has a weight rating of 14,000 pounds, which if you take that off of the 26, leaves me with 12. So that’s why this guy here is rated for 12,000 pounds.

Now the general weight rating of pickup trucks is going to, it’s probably gonna vary a little bit, but generally speaking, a one-ton dually, like this is gonna be 14K, a single rear-wheel, one-ton truck is going to be 12K, and a three-quarter-ton truck is gonna be 10K. So if you think about that sort of logic, if you want it to tow a 14,000 pound trailer, you would need a single rear-wheel truck, a one-ton or a three-quarter-ton.

So now the real like maximum, real weight rating of this thing would be something like this. You’d have the total capacity of both axles, in my case that’s 14,000 pounds plus what the trailer is gonna put onto the truck, so that’s gonna be, let’s say another 1,500 pounds. The actual like maximum physical capacity of this thing would be 15,500 pounds. But in my case, I wanna keep the combination set up so that the driver of this truck, either myself or someone else does not need a commercial license to tow this combination.

So with the rating of 12,000 pounds minus the actual empty weight of the trailer, that puts me just over 9,000 pounds of payload capacity, which for what I’m doing is plenty. You also might notice that I have this thing stripped down for that measure, I guess. So for the registration purposes, I wanted to have a number on the absolute maximum I could put on here, so if I was needing to get the most amount of weight on here as possible, I can remove all the unnecessary accessories and gain back a little more capacity. So without the winch, and the arch, and the rear jacks, that saves 400 pounds of weight that I could use to haul something when I don’t need those things. If I was moving some machinery, or a piece of equipment, or something, and I needed to get up a little bit higher, I can just pull those things off and get that a little bit extra capacity. But even with the winch and all the other stuff on there, that’s still a what, eight-and-a-half thousand pounds, a little bit over that, 8,600 pounds. That’s a lot of logs, that’s a really big log if it’s just one, and that’s way plenty for what I’m doing, especially with short trips locally, this being an urban logging trailer specifically, it’s made for quick pickups around the city, so multiple trips, that 8,000 pounds, that’s a lot of logs.

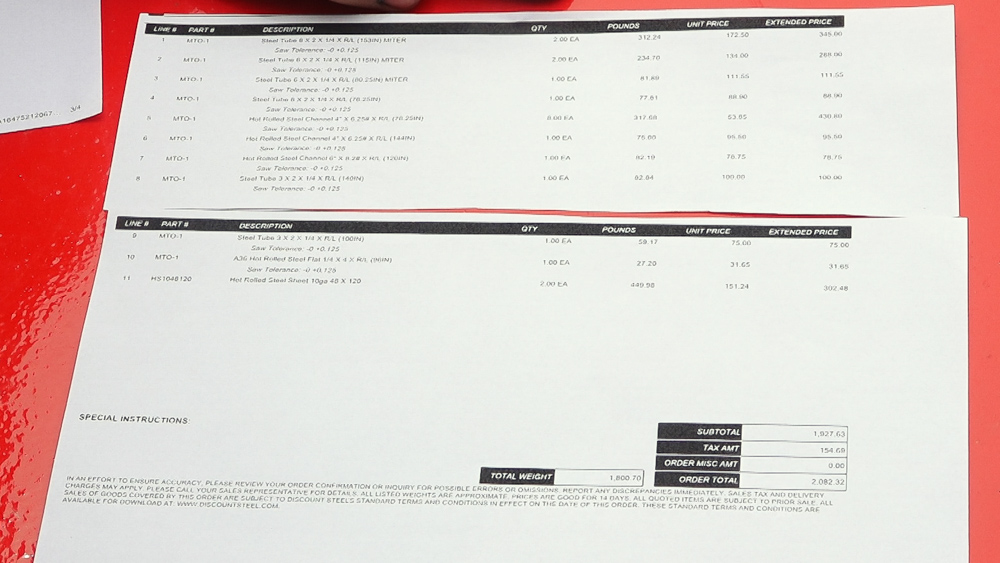

Next, let’s talk a bit about what I spent. This is the main order for the steel. So you can see how much everything costs, and again, it’ll tell you how much everything weighs too. So this a realistic expectation there just for the main frame essentially, the arch, and some of the other accessory things. Approximately $2000 in steel.

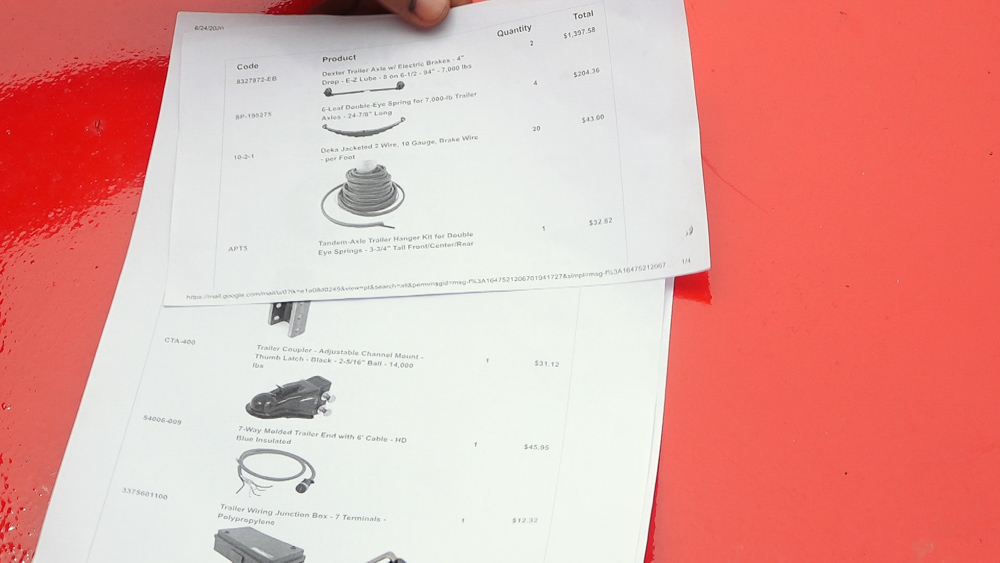

So next will be the more expensive things actually. These are the trailer related things. So on here, we got the axles which are $700 a piece. Those are Dexter EZ Lube axles, you got the springs, the suspension alone is another 200 bucks. As we get down here, we get to the infamous tires. I mean $1,400 for tires. So I always laugh when people are like, you have so much money and steel in this thing. You have no idea. The steel is the cheap part . There’s the weld-on adjustable coupler bracket thing, you know, the coupler, the junction boxes, the harness. The wiring harness alone, 45 bucks and you got a breakaway battery and some lights and things. So $3670 for trailer specific parts.

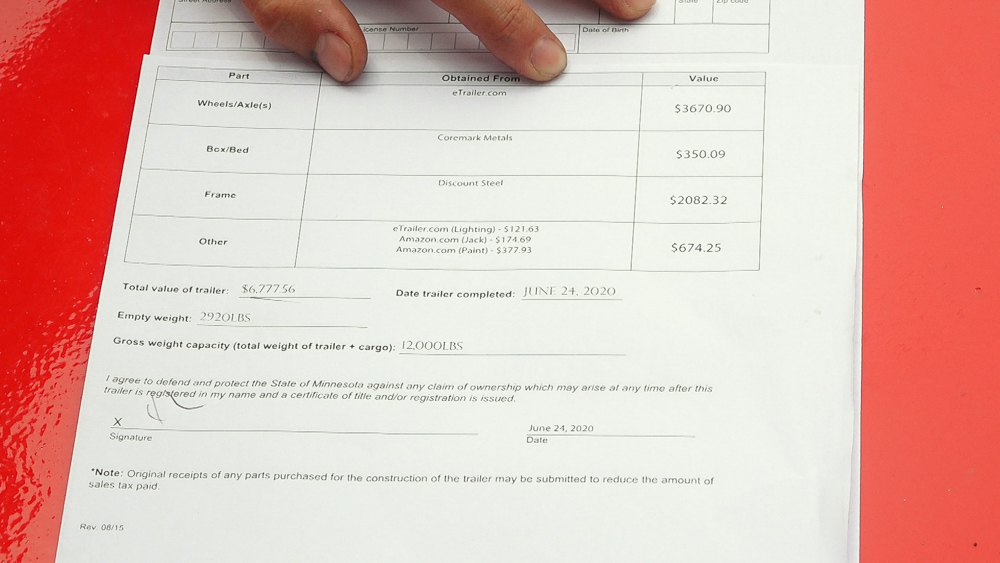

So we’re at $2,400 in steel, we’ve got $3670 for the wheels, axles, and everything else trailer related. I’ve got the jack, the paint, and some more lights here for another almost $700, so my total all in cost is almost $7,000. $6,777.56. So with that information all figured out, we really have everything we need to go to the DMV and apply for a title and a license plate, so we would take this form, all the receipts, those pictures with us, and we’re going to get a application for title to fill out.

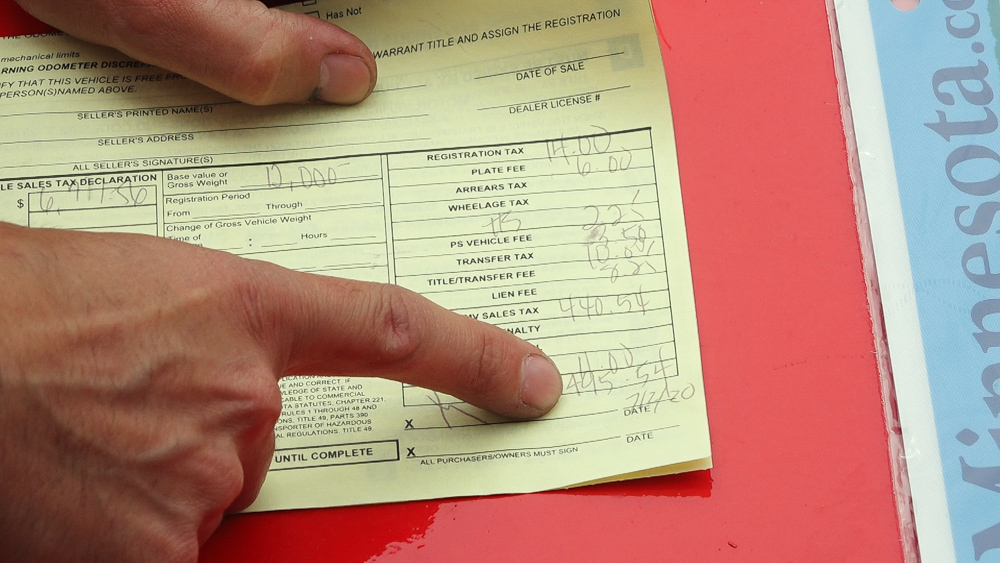

On here, they’re going to figure out how much you owe in taxes for registering this thing, so let’s take a look at that and we’ll add it to our total of my total, all-in costs on this build. So you’ll stand at the counter, they’re gonna punch some stuff into a computer, and they’re going to fill in all the fees you owe for your trailer, so my all in total was $495.54, so basically another 500 bucks. So I’m at 7,250 ish total.

So here in Minnesota, they’re gonna send you home with your plate on the same day, and your title will come in the mail. And as you can see on here, it’s an F class, which is 12,000lbs.

At this point I’m absolutely ecstatic. It’s finally time to move over from my old trailer to the new one!

On goes the arch!

Popping some Prosecco to celebrate!

This trailer is going to get dinged up and they say the first scratch is the hardest.

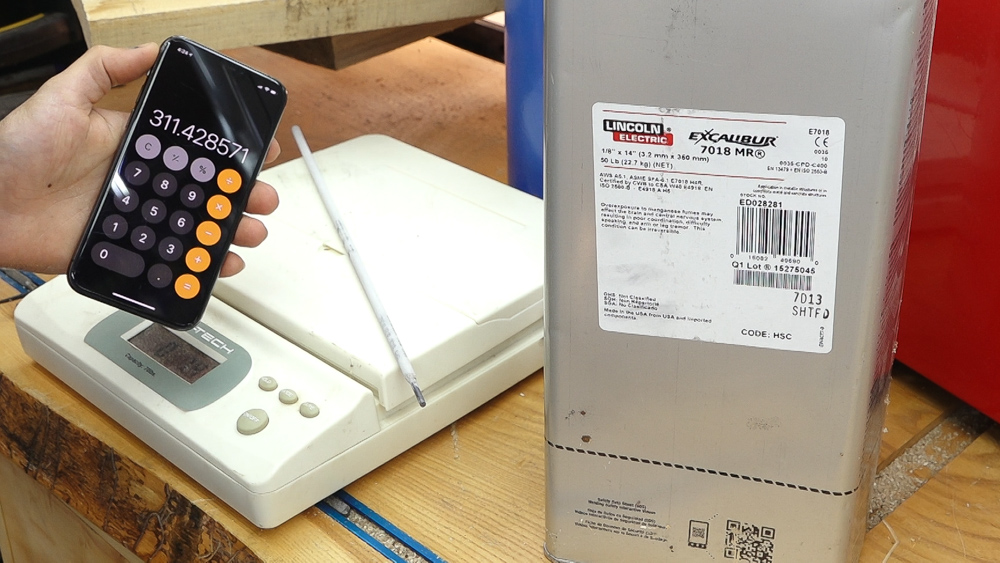

So real quick on the welding consumable side of what I used. I use two of these 20-cubic-foot tanks of MIG gas. As far as MIG wire goes, this is my second 12-pound spool that I have on here, and that’s a spool is probably about half gone now.

Now for the most exciting part, how many stick electrodes did I use? So that tin started out as 50 pounds. It was a full when I started the project and it has dropped in weight by 27 pounds, four ounces. Doing the math to determine how many sticks that is leads me to 311 electrodes consumed. That’s a lot of welding!

So now lastly, let’s talk a bit about, is it worth it to build your own trailer? And you know, for that, it’s gonna be a big depends sort of thing. So, first off, this is obviously a homemade trailer, I’ve built this thing myself, and also it’s a fully custom trailer, so it is exactly the trailer that I wanted. So this is not like an off-the-shelf kinda thing, so regardless, if you wanted something like this, you would have to have someone make it for you custom, so it’s not gonna be as inexpensive as any other trailers so keep that in mind. I think for most things though, in life, if you look at doing them yourself versus paying someone to do it, it’s probably cheaper as far as opportunity costs go, to have someone else build things for you. However, in case of this, I just enjoy making things, and I really, really enjoyed the journey of making a trailer. I got so much fulfillment out of the process of actually building it, and now that it’s done, I have so much pride in being able to say that I built this thing myself in my backyard. So for those factors at least, I am super glad that built my own trailer. One advantage building it myself, gave me over having someone else build a custom trailer for me, is I have absolute, complete control of everything that went into the build. I know every little part of it, I know that there were no corners cut anywhere, so there’s a lot of value there for me at least to know that everything is exactly as I wanted it, as far as the design goes and as far as the construction goes as well. And one possibility too, was a hybrid, I guess, of sorts. So you could have the trailer custom fabricated by a fabrication shop, and then you could handle all the wiring, and the paint, and whatever else there so you can be sure you have the exact wiring job you want, and you can be sure you have exactly the tires and the axles you want, and all the other stuff. So you could always piecemeal it out too, but man, I am so glad that I built this thing by myself in my driveway. There is just so much pride in being able to say that, and now that it is a functional rolling trailer, that is just a huge win for me. This is not something I thought I’d ever be able to do, especially a couple of years ago before I even knew how to weld or anything about trailers, just the idea, the concept of building a trailer yourself just seemed so foreign and strange to me, so this is a big milestone for me, at least just as far as confidence goes.

So I guess for that reason itself, I am again, super glad that I built it. And obviously, the best part of this whole thing is the fact that it actually works. So check this thing. No problem getting a log this big up here. This is what this trailer is designed to actually get. Logs this size is right on par with what I had in mind for it. It towed perfectly well, like the smoothest tow I’ve ever had in my life. It’s so smooth, it follows right behind the truck, absolutely no problems, so the time that I invested making sure my axles were aligned correctly, and everything was laid out well, really, really worked out well for me.

So I really hope you enjoyed the build series, maybe inspired you to build your own trailer, or just take a look at trailers differently as well. I know for me, before I knew a whole lot about trailers, I didn’t know what I was looking at, and I think after watching this build, you’re gonna be very surprised with the other trailers you see rolling down the road.

Welcome to my shop! This is a quick update to let you know what I’ve been up to. This big chunky thing is the leg

Welcome back to the home renovation. This time I’m going to be working on the kitchen island. Here is a small model of the island.

Welcome back to our home renovation. Today I am going to be working on this wall. It needs some upper cabinets and the surround for