Kitchen Island, Barn Power – March 2024 Update

Welcome to my shop! This is a quick update to let you know what I’ve been up to. This big chunky thing is the leg

This hanging bed swing is an incredibly comfortable way to spend an afternoon. The swing is sized for a twin size mattress and is suspended from ropes which with a light breeze will rock you to sleep or if you’re not tired, it’s a great place to lounge and read a book.

The ash I’m using for the frame came from a log I cut with my chainsaw mill about a year and a half ago. It was the first log I picked up after adding the new arch mounts to my trailer. This log turned out to have a carpenter ant colony in it so there was a lot of damaged wood from the ants tunneling as well as some rot that was starting to form.

All those issues made these slabs ideal for breaking down into smaller parts since they would be challenging to use whole. I started by finding the largest parts: the front and back rail for the support frame. I drew a straight line to use for reference and cut along it with a circular saw. This first slab also gave me many of the smaller parts for the sides of the bed.

The other long rail and the back rail came from a second slab from that log. You can see how extensive the ant damage was in this slab.

All of the rough parts get flattened and squared up on the jointer. I planed them to thickness and ripped them all to width. The sizing for the frame parts are the equivalent of 2x6s and 2x4s with their rounded corners removed. The support frame parts are 5″ wide and the rest of the frame parts are 3″ wide.

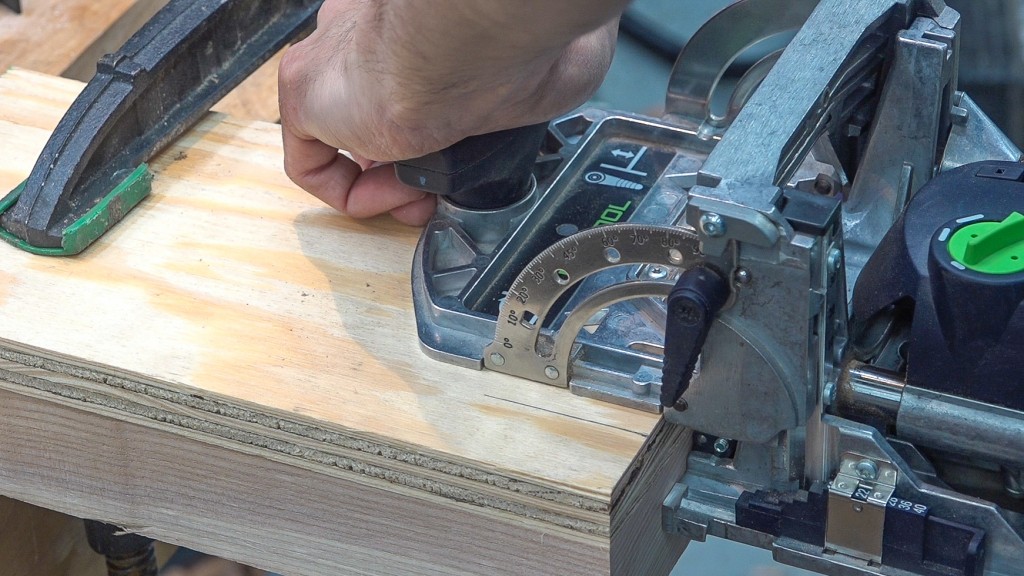

I’m using the domino for the joinery on the frame but any nonintegral joinery method would work equivalently such as dowels or pocket holes. Since the stock is thicker, I’m stacking two rows of dominos (I used 10mm dominos since I had a lot of those to “get rid of”). To create an offset without moving the fence, I used a scrap of 3/4″ plywood. I’d make one pass with the plywood under the fence to make the top row and then remove the plywood to make the bottom row. I started by cutting the domino mortises into the ends of the short support frame parts.

Next to make the mortises into the long rails, I clamped a stop to the rail to give the bottom of the machine somewhere to reference against. I set the edge of the plywood at the location where I wanted the short rail to start and made sure it was square to the edge of the long rail. I again use a scrap of 3/4″ plywood to create the offset between the rows of dominos.

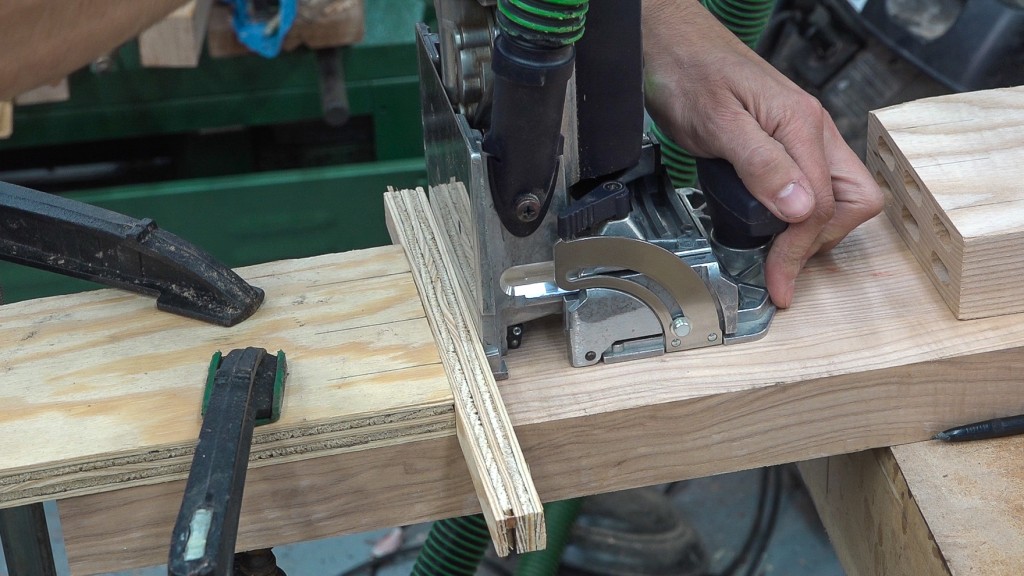

With the joinery on the support frame complete, I can move on to joining the uprights. Again I need to use the machine with the fence folded up so I need to a way to reference the machine off of. I used another scrap of plywood with a L shape cut out that can be clamped to the inside of the frame. Again I’ll make the two rows using a scrap of 3/4″ ply to create the offset and since these frame parts are narrower, I’ll just use 2 rows of 2 dominos.

With the uprights in place, I can start filling out the rest of the side frames. I cut the first miters on the front side and added dominos to those parts. Next I can mock everything up with the angled piece and the top piece still long so I can mark the exact cut length for those parts. The top piece should be parallel to the frame, the uprights should be flush to the front or back and the one miter should be closed.

Using that mark as reference, I can mark out the cut lines, cut the miters on both parts and add their dominos.

A test fit confirms that everything fits correctly.

Next up is the curve in the angled rail. I used a drawing bow to make drawing the curves easy since I work alone. I set the bow to a curve that will intersect the two outside point and the offset in the middle. The bow is set to a second curve to do the same thing on the inside. The lines are cut at the bandsaw and cleaned up with the spindle sander. The last part of the frame is the long back rail. That gets joined to the rear uprights with the same domino configuration as the rest of the frame.

Next the panels can be added. I started with a couple of sequential cherry boards about 12″ wide. They had a large knot in the center that I’m going to use to my advantage. For the long back panel, I’ll center the knot in the panel to make a nice symmetrical grain pattern. On the shorter sides, I’ll put the knot where the cut out for the curved rail will go. This will remove the knot and leave a grain pattern that follows the curve of the frame.

To make laying out the size and shape easy, I can use the side frame as a template. I lay the frame on top of the panel with the panel extended a bit under 1/4″ on the bottom and trace around the frame. These lines can be extended by a bit under 1/4″ and the panel can be cut to side. The extra size will allow the panel to fit down into the grooves that will be cut into the frame to receive the panel.

The panels are finish prepped and prefinished. I’m using an outdoor finish on this project which will help protect it from UV light and some precipitation.

The grooves can now be cut into the frame parts. I use router with an edge guide and a 1/2″ spiral bit. I take some time to set up the fence so that when the fence is run against each face of the frame part, the resulting groove is a nice snug fit for the panel. You want this fit to be spot on so debris can’t find their way into the groove over time. Having the panels completely sanded and finished before cutting these ensures the panels will end up fitting perfectly.

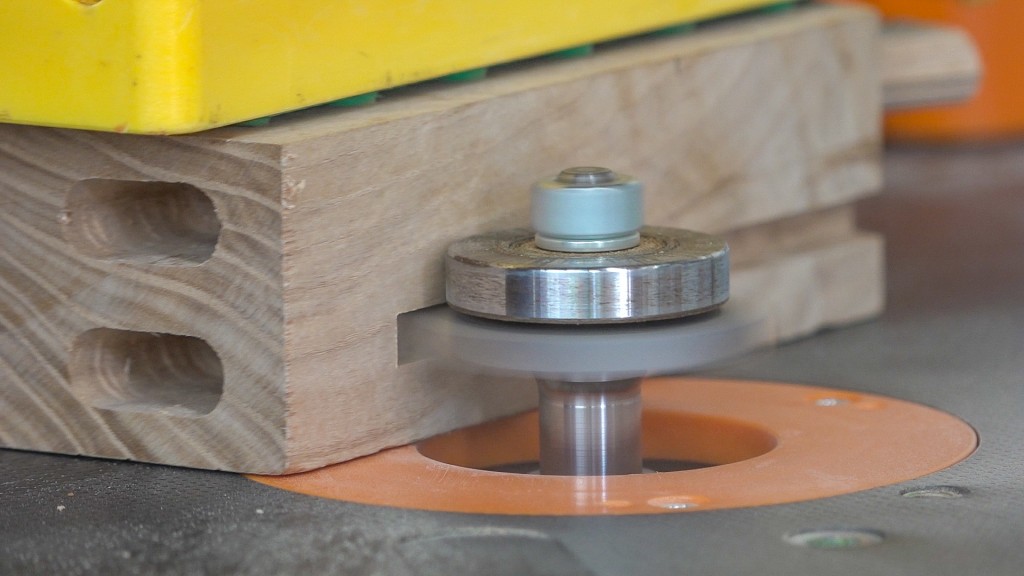

Some of the frame parts are a bit small and could be awkward to cut with a handheld router. So the curved part and the front upright are cut at the router table with a slot cutting bit.

While the frame is disassembled, the last bit of detail work can be added to the long rails. They need a whole drilled at each end and I cut a wedge off the bottom corner to add visual interest (and to remove some defects)

The frame parts get their final sanding and the glue up can begin. I’m doing this in multiple phases to make this process much easier and I’m also using epoxy so I don’t have to worry about the glue setting up before I get everything together. The first phase is to get the support frame glued together.

Next, the rear frame and panel can be added. The panels need to float so I’m careful about glue potentially dripping down from the tenons onto the panels.

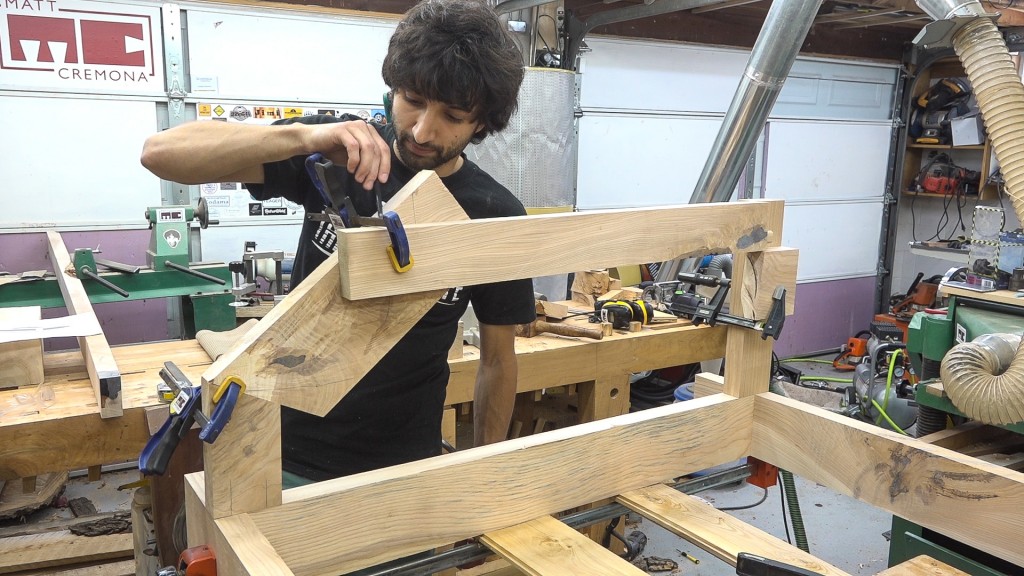

Lastly the sides can be added. The frame needs to come together at a bit of an angle.

A clamp can be added to the frame on both sides of the miter and then another clamp can pull against the clamps to fully close the miters. The last bit of assembly is to add the ledger to the inside of the frame which will hold the mattress support boards.

The frame gets a quick pass with a sander to flush up anything and clean off any glue squeeze out. I lightly broke the edges with a block plane and sandpaper. The front edge of the support frame get a heavier roundover since your legs will contact that edge.

The frame can receive a finish. I used 3 coats of Outdoor Oil which is the same finish I used on the panels.

Lastly the mattress support boards can be added. These are 1x4s that are screwed into the ledger. I tapped the holes for machine screws but countersinking regular wood screws would work equally well here.

To hang the bed, I used three lengths of 1/2″ sisal rope that I braided together. To secure the bed to the rope, I looped the braided rope through the hole and unbraided about 12″ of rope from the end. I then took each strand and braided it back into the main line for a clean double braid look.

Dust Mask: http://amzn.to/2vCprwt

Triton Circular Saw: http://amzn.to/2tUcpbU

Domino: http://amzn.to/2vCWLDG

Miter Saw: http://amzn.to/2eJ06xa

Router: http://amzn.to/2hXj5AC

Spiral Bit: http://amzn.to/2gXAzky

Router Table: http://amzn.to/2sbcLLt

Slot Cutter Mandrel: http://amzn.to/2vTHOMQ

Pushblock: http://amzn.to/2tUd3WS

Triton Track Saw: http://amzn.to/2f2P85l

Epoxy Resin: http://amzn.to/2vTGCJm

Epoxy Hardener: http://amzn.to/2uRhwy9

Outdoor Oil: http://amzn.to/2urdlba

1/4-20 tap: http://bit.ly/2vCOG1T

Welcome to my shop! This is a quick update to let you know what I’ve been up to. This big chunky thing is the leg

Welcome back to the home renovation. This time I’m going to be working on the kitchen island. Here is a small model of the island.

Welcome back to our home renovation. Today I am going to be working on this wall. It needs some upper cabinets and the surround for

4 Responses

just I love watching you work just wish I could do half the things you do

thank you!

Awesome job Matt! Love it thanks for the fun.

Thanks Mark!