Kitchen Island, Barn Power – March 2024 Update

Welcome to my shop! This is a quick update to let you know what I’ve been up to. This big chunky thing is the leg

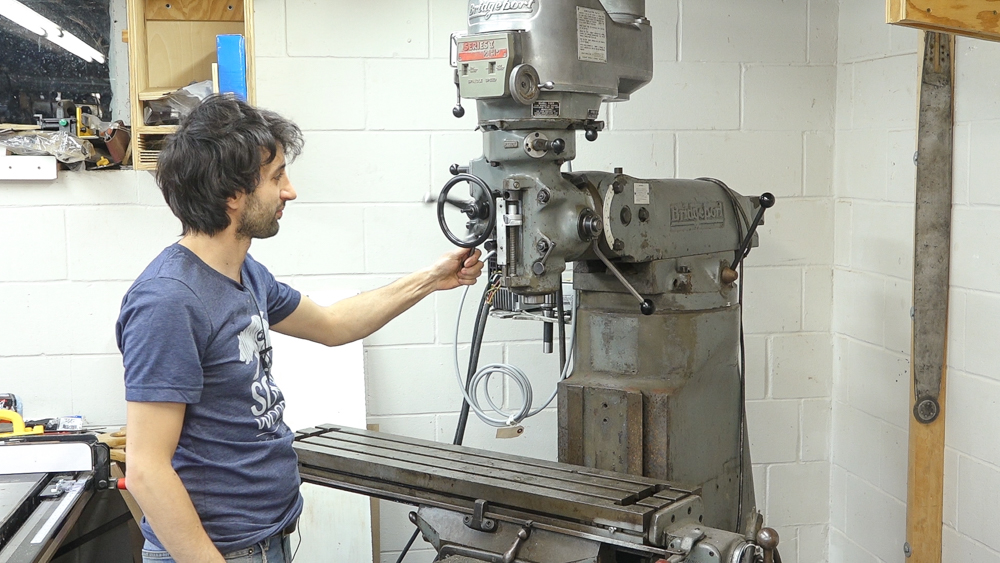

About a month ago, I bought a Bridgeport milling machine. The machine is in good shape but could use a really thorough cleaning. This time we’re going to get started by cleaning up the tooling that came with it and start cleaning the machine by cleaning the head.

To make this process a bit easier, I want to start cleaning up the tooling that came with the mill. All of these items are pretty dirty and the best place to store them is on the dirty mill table. If I get them cleaned, I can put them somewhere else and there will be fewer things in my way as I start cleaning the mill. Since it’s the biggest, I’ll start cleaning the vise starting with the main vise and then coming back for the swivel base.

I disassembled the vise to be cleaned. This thing was really messy.

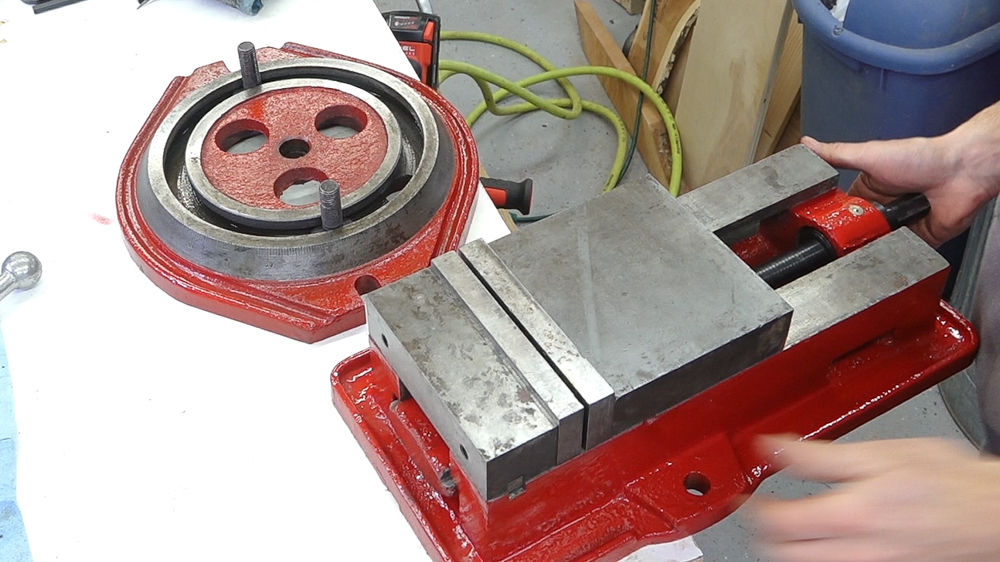

All of the vise parts soaked for a bit in degreaser. I gave the a quick scrub with a brush and dunked them in clean water. Everything was wiped dry with a paper towel and then a coat of Boeshield was applied.

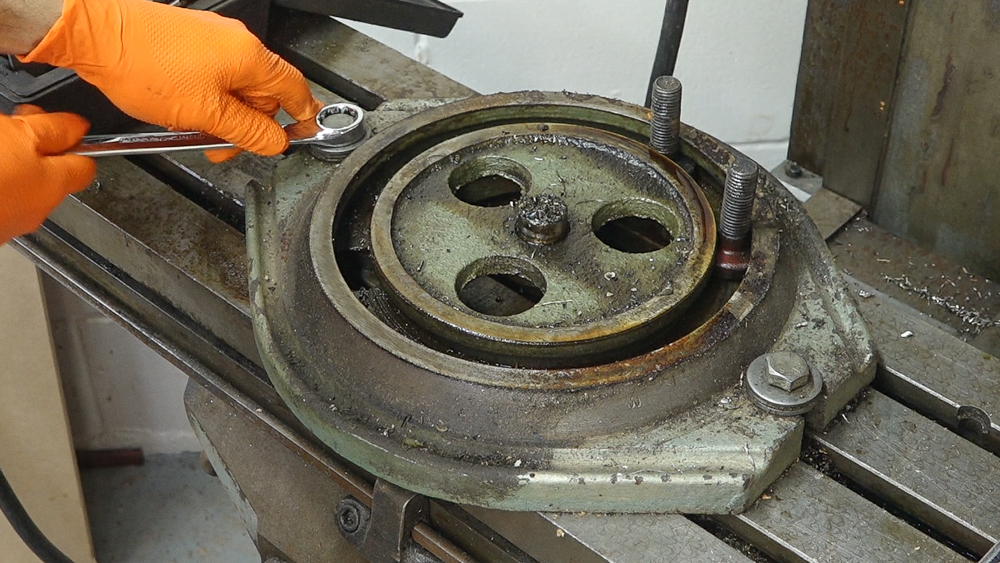

Next was the swivel base which may have been even more dirty than the vise.

Originally I wasn’t going to paint the vise but decided to anyways. It looks a lot better than it used to!

Next I could move on to the tooling bins. The mill came with a lot of end mills however most of them would need to be reground. I washed these in degreaser to remove the surface grime which made it much easier to assess the condition of the cutting edges.

The second bin contained the larger end mills and collets. These also cleaned up nicely.

I also cleaned up the set up kit and the parallel kit. Both of these were pretty grimy and had chips stuck down in the case/holder.

With the tooling out of the way, I can move on to the machine. I removed the DRO shelf to get it out of my way and started working top down.

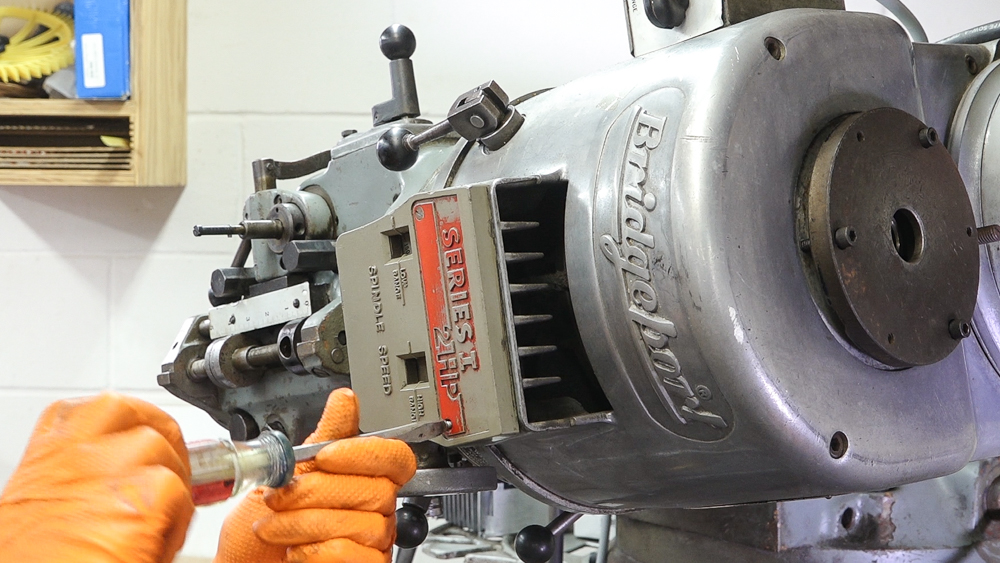

Tipping the head made the top much easier to clean. I removed the top spindle bearing plate, motor cover, motor fan, and motor shroud so they could be cleaned off the machine. As I work through this process, I’ll remove anything I can to make cleaning easier.

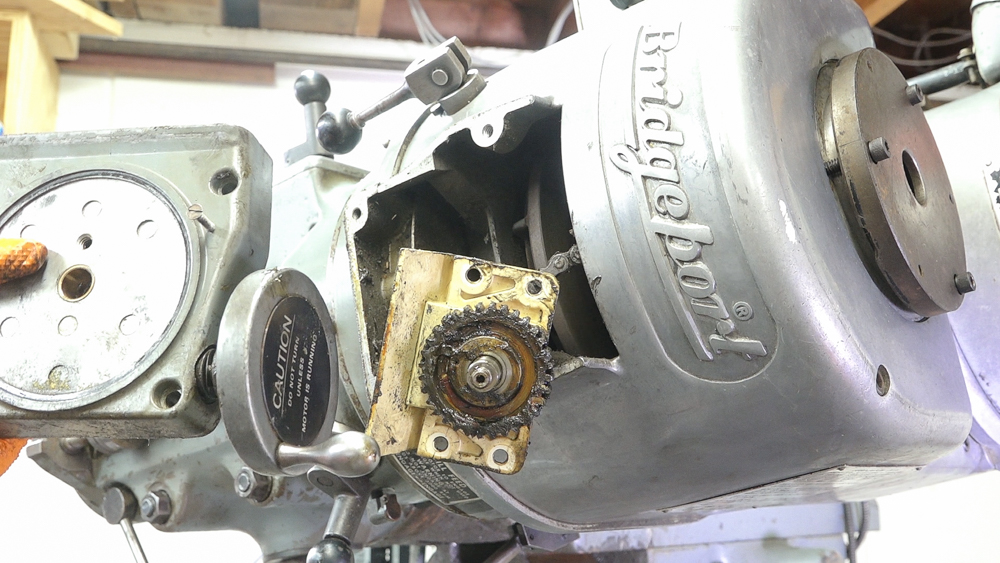

Next I can move on to the variable speed control. Looking down into the head I could tell that there was a good amount of dirt inside. Most of it looked to be belt dust from the belts wearing over the years.

With the variable speed control taken off, I could clean that separately. I did my best to clean out the head with a vacuum and compressed air and inspected the belt.

With everything cleaned up, I can start reassembling the speed control, apply fresh grease to the worm gear, and bolt the assembly back onto the head.

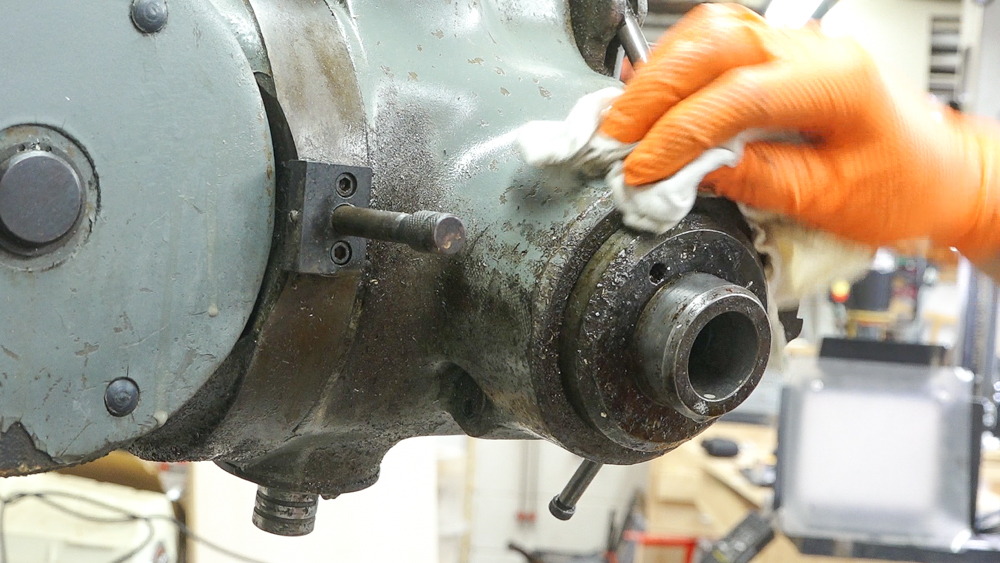

The last thing to address while the head was tipped was the underside of the quill. Years of oil and chips splashing up have coated this entire area. I found the best way to clean this was to wrap it in a rag soaked in degreaser.

After some soaking and a bit of scrubbing, the quill looks so much better!

I uprighted the head and I’ll work on the left side next. I’ll pull off the downfeed speed selector and downfeed engagement to clean them off the machine. Taking these parts off also allows me to clean the area of the head obstructed by these parts. Once they’re cleaned, they can be reinstalled.

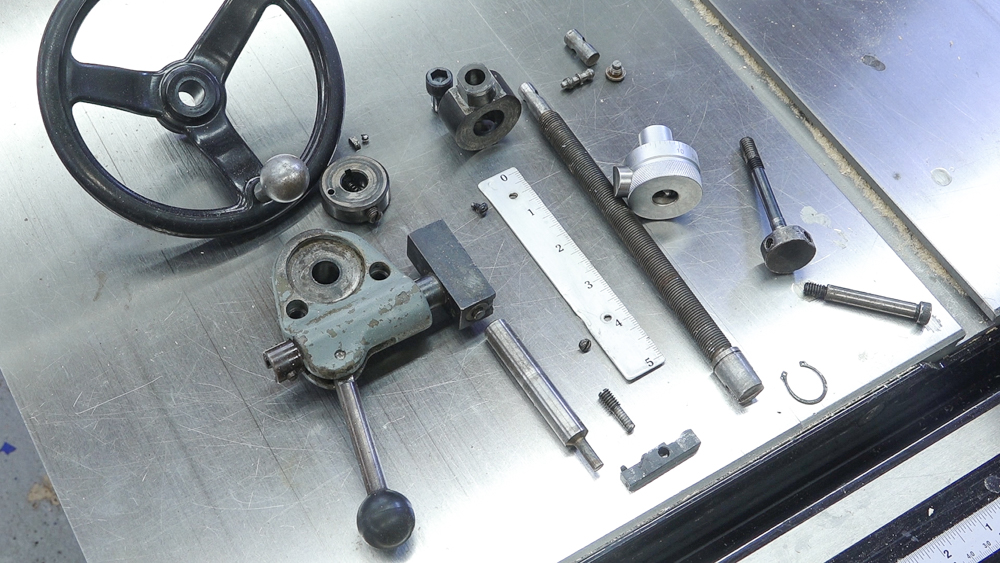

Next up is the front face of the head. This area is where all the quill controls live. I stripped everything off so the parts can be cleaned and to give me access to the areas of the head obstructed by the parts.

Just for fun, here are all the parts that go on the front of the head and control the quill. I also chose to swap the depth stop with a quick stop. This style has a release so it can slide down the rod instead of having to turn the stop all the way to the desired position.

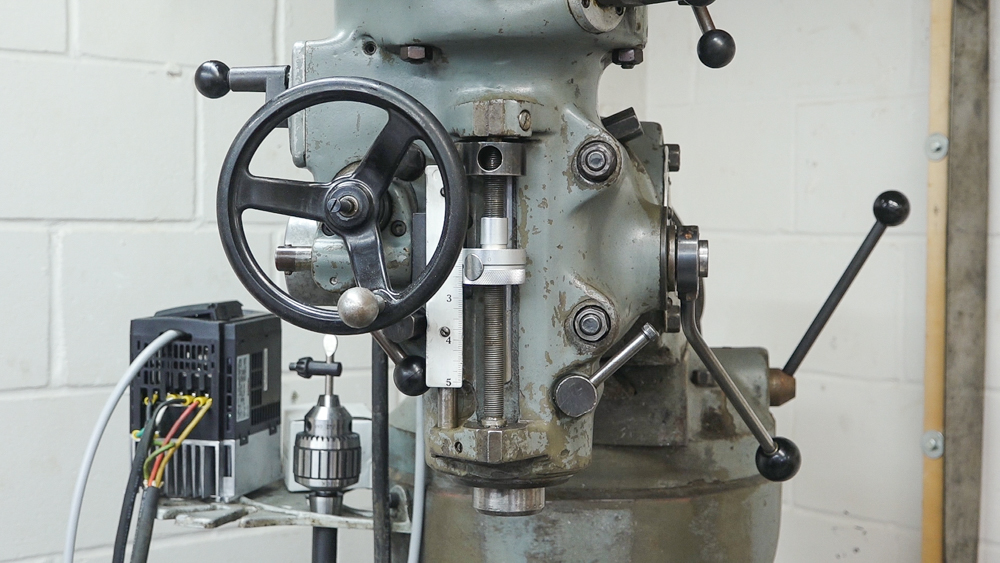

Here’s a look at the front of the head after cleaning.

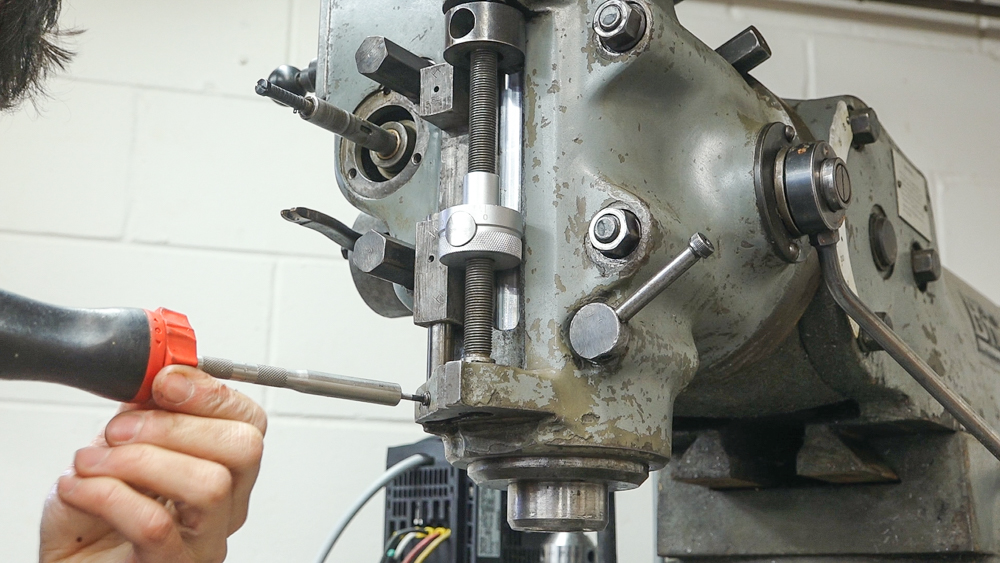

Everything can be reinstalled. This was a surprisingly quick process. I was really impressed with how easy these machines are to work on.

There’s the front of the head with all the parts reinstalled.

Now for the moment of truth: after removing and reinstalling all those parts, does the head still work. To my surprise: yes 🙂

That’s where I’m going to end this one. Next time we’ll continue down the ram and column and start digging into the table.

Welcome to my shop! This is a quick update to let you know what I’ve been up to. This big chunky thing is the leg

Welcome back to the home renovation. This time I’m going to be working on the kitchen island. Here is a small model of the island.

Welcome back to our home renovation. Today I am going to be working on this wall. It needs some upper cabinets and the surround for

2 Responses

have you tried to find a repair manual for the mill? or even an owners manual? have you tried to find parts for it and what do the belts look like.

I did the same and more to the one i have.

It works great

A real workhorse